Whether you are starting a new printing business or want to make custom t-shirts for your group, you will have two options in printing: Screen or DTG. While screen printing is old-school and great for tough prints and special effects, DTG printing gives you an edge over color choice and printing time.

Let’s look at how DTG printing works and how it differs from traditional screen printing.

What is DTG Printing?

DTG, known as Direct to Garment Printing, is a method in which a water-based ink prints the design or image directly to fabric via a DTG printer. In DTG printing, there is no need to create screens or stencils and use colors layer by layer for the design to be complete. You get detailed plans and color variance in a single layer of ink.

How does a DTG printer work?

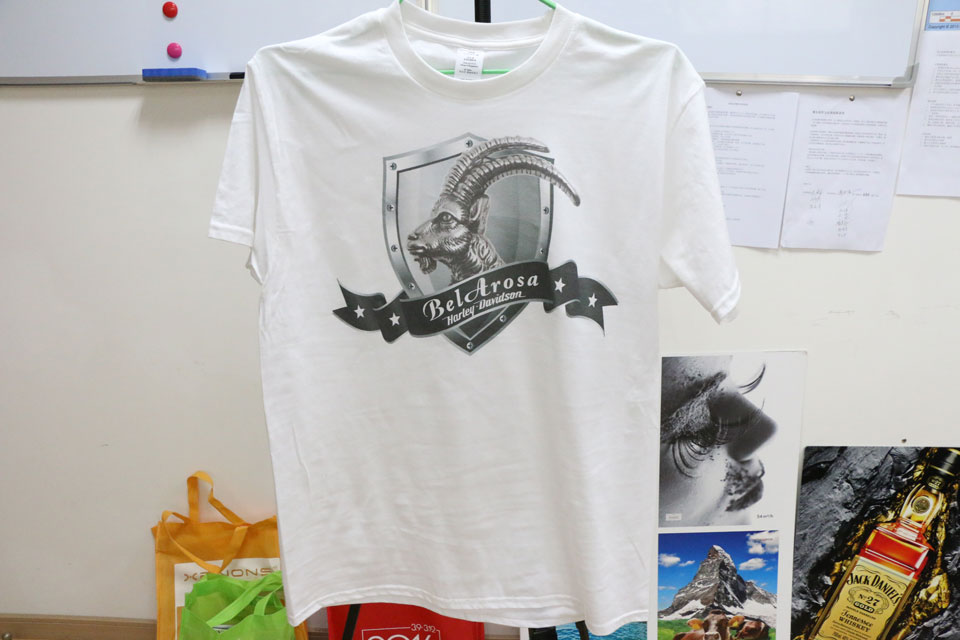

Just like the ink-jet printer transfers the image or text on paper, the DTG printer prints them on a blank T-shirt. The ink is water soluble and absorbs into the fabric quickly, giving you smudge-free and flawless prints in minutes. You can print complex designs or images with a high level of detail using a DTG printer.

What Designs are best to print with a DTG printer?

Images, complex art, or designs with loads of colors are best to print with a DTG printer as it gives you flexibility and color variety. With DTG printing, you don’t have to restrict yourself to colors like in screen printing. DTG printing is suitable for customized orders as well as for bulk printing and takes less amount of time for production.

Benefits of Using a DTG printer

DTG printers are getting more hype these days, and that is due to their ease of use, color variability, and flawless printing of complex designs. Some of the key advantages it has are:

· Flexibility

Whether you want a single shirt or 100 a DTG printer can perform both without an issue. It is excellent for small startups who don’t have to invest in making stencils or screens and have limited options for printing.

· More Variety

With DTG printers, you have a wide color range making your prints look unmatchable. So for elaborate designs where you need the right color shades, like images or portraits, DTG printing gives defined and meticulous patterns. The printer offers any colors and has blending options to create the right color, giving you flawless printing that matches the image or design.

· Better feel

DTG printers transfer the design on the fabric in a single layer of ink, unlike screen printing, which uses multiple ink layers. Due to this, the material remains soft and breathable, giving the customer a better feel and comfort.

· Eco-friendly technology

Another impressive aspect of using DTG printers is that they are eco-friendly and create less waste than screen printing.

· Superior finish

Using a DTG printer, you get complex prints with perfect detailing, striking finish, and quality. DTG printer gives you impeccable designs and quality that are hard to match with screen printing.

· Faster set-up and product deliverance

Setting up a DTG print takes less time, and you are good to print instantly. The printer delivers fast prints, which dry out within minutes so that you can produce bulk amounts in a day without an issue.

Differences between DTG and Screen Printing

Both screen printing and DTG are popular printing technologies and have their pros and cons. Here is a comparison between both so you can weigh in your options and pick the best one for your printing business:

· Cost of Printing

Initially, a DTG printer costs more than screen printing, but for customized orders and later printing, DTG is more economical. However, for bulk orders using a DTG printer might cost you more, while using the same screens for printing hundreds of shirts will be cheaper.

· Manufacturing time

DTG printing is a whole lot faster than screen printing. The print takes less time to dry out, and you are ready to ship the product within a day.

· Durability

The screen-printed designs are more long-lasting and durable than DTG printing. Due to multiple layers of ink, the print will fade away in 25 percent more washes than in a DTG-printed design.

· Design versatility

You can print any simple or complex design with a DTG printer while you are restricted to screen printing. In DTG printers, there is no limit on colors and detailing, while with screen printing, you have to pick simpler designs using 3 to 4 shades of colors.

· Consistent prints

With DTG printing, you get the same print on each item without an error; in screen printing, there are morechances of error or design difference.

Are DTG printers worth it?

There is no need to limit your creativity when you can print your designs on your t-shits using DTG printing. Using a DTG printer gives you more production in less time with high efficiency and design quality. From single print to bulk orders, DTG printing gives you the same performance and finish.

It’s higher on the investment side, but it will be worth every penny spent on it and is excellent for graphic designers or artists looking for a side hustle to generate income.

Summing it up!

DTG is a sustainable and greener printing option for businesses. Also, if you are new to the industry and want to print a couple of pieces for testing and survey, then DTG is better than screen printing. You get high detailing, more comfort, and faster production with DTG printing.

Considering its color options and precision in printing intricate designs, DTG printers beat screen printing and are preferable.

FAQs

1. How long does it take for DTG to print a T-shirt?

On average it takes 2-5 minutes for printing a t-shirt with a DTG printer.

2. What technology does a WER DTG printer use for printing?

The WER DTG printer uses ink-jet technology to create high-quality prints with water-based ink that soaks in the fabric of shirts instantly.

3. What is the cost of a DTG printer?

The price of WER DTG printers starts from $3-5K, while the premium ones can cost up to $7-8K. You can inquire at the official website: WER DTG Printer

4. Are DTG prints long-lasting?

Yes DTG printed shirts don’t fade away quickly, and you can still have good color and design finish for 40-50 washes.

5. Which type of printing is better for customized orders?

DTG printing is the best option for single customized pieces as you don’t have to create a stencil or screen for just one-time use.

Tags :

Knowledge & Stories| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| 21 | 22 | 23 | 24 | 25 | 26 | 27 |

| 28 | 29 | 30 | ||||

Recent Posts

- Ultimate Guide to UV Printing: Insider Tips and Tricks

- Before You Invest: Choosing a Large Format Flatbed Printer

- Maximizing Brilliance: Mastering UV Printer Settings for Optimal Media Reflectivity

- The advantages of using a WER UV printer for large format printing (2)

- Achieve Stunning Results in Home Décor and Architectural Design with UV Printer

Archives

- January 2025

- November 2024

- September 2024

- March 2024

- December 2023

- November 2023

- October 2023

- May 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

- December 2017

- July 2016

- June 2016

Recent Posts

- Ultimate Guide to UV Printing: Insider Tips and Tricks

- Before You Invest: Choosing a Large Format Flatbed Printer

- Maximizing Brilliance: Mastering UV Printer Settings for Optimal Media Reflectivity

- The advantages of using a WER UV printer for large format printing (2)

- Achieve Stunning Results in Home Décor and Architectural Design with UV Printer

Recent Comments