Do you want to customize something too big for your printer to handle? Well, your application might be versatile, but the UV printing machine is the ultimate solution to your problems. From making yard signs or directional signage to printing mass production of promotional products, UV Printers offers a solution to every need of yours. Propel your business to new heights with attractive layouts that attract customers.

UV simplifies and speeds up printing to meet the increasing demand for limited runs of decorated products. Moreover, it adds a layer of sophisticated and exciting textured special effects to the end result. Add vibrant color and outstanding textures to your pens, smartphone cases, bottles, etc.

What Is A UV Printer?

While printing, UV printers, a type of digital printing, use ultraviolet lights to dry or cure the ink. Specially designed UV lights closely follow behind as the printer distributes ink on the surface of a material (called a “substrate”), instantly curing or drying the ink.

Initially developed for quickly drying gel nail paints during manicures, UV light uses swiftly grew into industrial and commercial markets. The UV lamps instantly dry any printed ink, producing much finer detail because the droplets of wet ink do not get enough time to spread out once printed. Further, UV-cured inks offer improved fading resistance and are more resistant to weather than others.

How Many Types Of UV Printers Are There?

Industrial UV printers print digital images directly onto a substrate. These machines use UV inks such as yellow, cyan, magenta, varnish, black, and white to reproduce stunning graphics on various materials such as glass, stainless steel, plastic, ceramic, and others. UV printing machines are commonly categorized into three primary models, including:

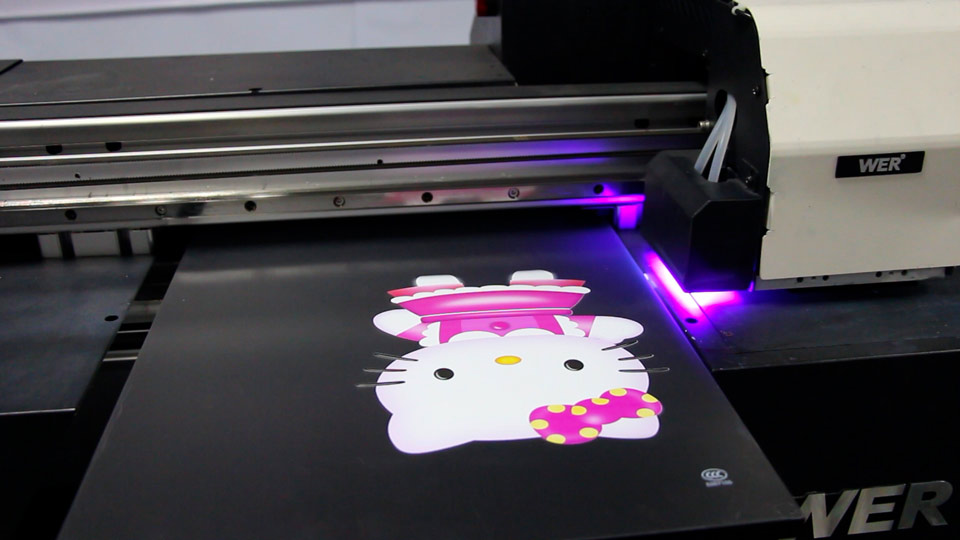

1. Flatbed UV printers

Flatbed UV printers are great for printing on flat surfaces like envelopes, plaques, papers, cards, and nameplates. It also covers flexible materials like cloth or canvas to increase convenience when dealing with a dynamic industry.

2. Roll to Roll UV Printer

The roll-to-roll UV printer combines large rollers with cutting-edge technology to print on your surfaces without leaving streaks or footprints. This printer is ergonomically designed to work with flexible surfaces such as fabric, car stickers, large paper sheets, and so on. It also has adjustable tension, allowing you to easily change the settings to maintain your preferred operation level.

3. UV Printer Rotary

Working directly on cylindrical shapes such as glassware, drinkware, candles, or plastic tubing is possible with a rotary UV printer. It also supports printing on sharp objects, which will help you manage multiple tasks in a busy industry. You can rely on the 360-degree full coverage to create full-color wrapped images on almost any curved surface.

How Does a UV Printer Work?

Traditional printing techniques involve special ink solvents that evaporate into the air during printing, usually upon application onto a material. Once the solvents have entirely disappeared, the ink dries up, creating a digital image. Solvent evaporation makes it easier for the ink to absorb into the substance. When it comes to UV printing, there are no solvents present in ink itself that are utilized for printing. Instead, the UV printing machine ink dries through a photomechanical process.

UV Printer produces the print following a few rapid procedures. Starting with applying ink onto the material that gradually follows the next step, specially designed ultra-violet lights emit the UV light on the ink, curing it instantly. Let’s observe the UV printer technology more closely:

- Print Head: UV printing machine uses Piezo print head technology to deliver incredibly precise ink deposition. An electrical charge is applied to microscopic piezoelectric components mounted behind the print head nozzles. As a result of this charge, the elements flex, ejecting exact amounts of ink with excellent control. Precise control over print quality, color density, and finish is possible thanks to the print head’s ability to produce precisely spherical dots of various sizes.

- Ink: UV ink flexibility allows printing over curved lines or onto elastic fabrics. Moreover, it instantly curies up, eliminating the need for the drying stage during the printing process.

- UV Lamps: The UV lights are cool-running, ozone-free, long-lasting, and economical LED bulbs. They don’t also require much time to warm up. Thus, accelerating the UV printing process by instantly drying the ink.

Advantages of UV Printer over an Ordinary Printer

Printing is an ancient art form that has undergone significant advancements over time. UV printing, being of today’s advanced forms, offers numerous advantages over an ordinary printer:

- Speedy & Consistent Prints: With UV Printer, multiple images may be printed quickly since the ink sets or cures in just a few seconds. Instant curing reduces the chance of ink distortion and produces consistent, accurate images.

- Durability – According to studies, UV-printed inks are more resistant to wear, rubbing, and tear than other eco-solvent inks, even in extreme weather.

- Vibrancy – Unlike traditional inks that quickly absorb into uncoated materials, UV ink dries when exposed to UV light and does not get time to soak into the paper. Thus, it settles on the uncoated sheet, leaving a more vibrant color to the print.

What Is The Average UV Printer Price?

The costs of inks and the machine with everything needed should be pretty straightforward. Most devices on the market today cost between $25,000 and $85,000. Some UV printers use bulk inks, while others use cartridges or bags, so comparing them will require some research. To calculate the cost per liter of UV inks in bags or cartridges, divide the cartridge price by the milliliter count and multiply by 1000. Ink prices range from $250 per liter to more than $700 per liter.

Someone who uses 2 liters of ink per month (about average for most small to mid-format users) could spend up to $6000.00 more per year in additional ink costs depending on which UV Printer type they choose!

Go to our website for prices: wer-china.com/product

Conclusion

As technology develops, UV printers can produce higher-resolution graphics, dramatically improving print quality far better than it could ever be with more traditional printing techniques like screen printing. From designing smartphone covers to creating lavish business cards, and everything in between, UV printing can cover it all in the most effective way to get fantastic results.

Tags :

Knowledge & Stories| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | |||||

| 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 17 | 18 | 19 | 20 | 21 | 22 | 23 |

| 24 | 25 | 26 | 27 | 28 | 29 | 30 |

| 31 | ||||||

Recent Posts

- Ultimate Guide to UV Printing: Insider Tips and Tricks

- Before You Invest: Choosing a Large Format Flatbed Printer

- Maximizing Brilliance: Mastering UV Printer Settings for Optimal Media Reflectivity

- The advantages of using a WER UV printer for large format printing (2)

- Achieve Stunning Results in Home Décor and Architectural Design with UV Printer

Archives

- January 2025

- November 2024

- September 2024

- March 2024

- December 2023

- November 2023

- October 2023

- May 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

- December 2017

- July 2016

- June 2016

Recent Posts

- Ultimate Guide to UV Printing: Insider Tips and Tricks

- Before You Invest: Choosing a Large Format Flatbed Printer

- Maximizing Brilliance: Mastering UV Printer Settings for Optimal Media Reflectivity

- The advantages of using a WER UV printer for large format printing (2)

- Achieve Stunning Results in Home Décor and Architectural Design with UV Printer