Regarding T-shirt printing, there are currently three printing technologies on the market: direct to garment printing, sublimation printing and screen printing. So, how do we choose a printer that suits us? Let’s talk a little bit about this knowledge.

First of all, we need to understand what is the meaning of direct to garment printing, sublimation printing and screen printing?

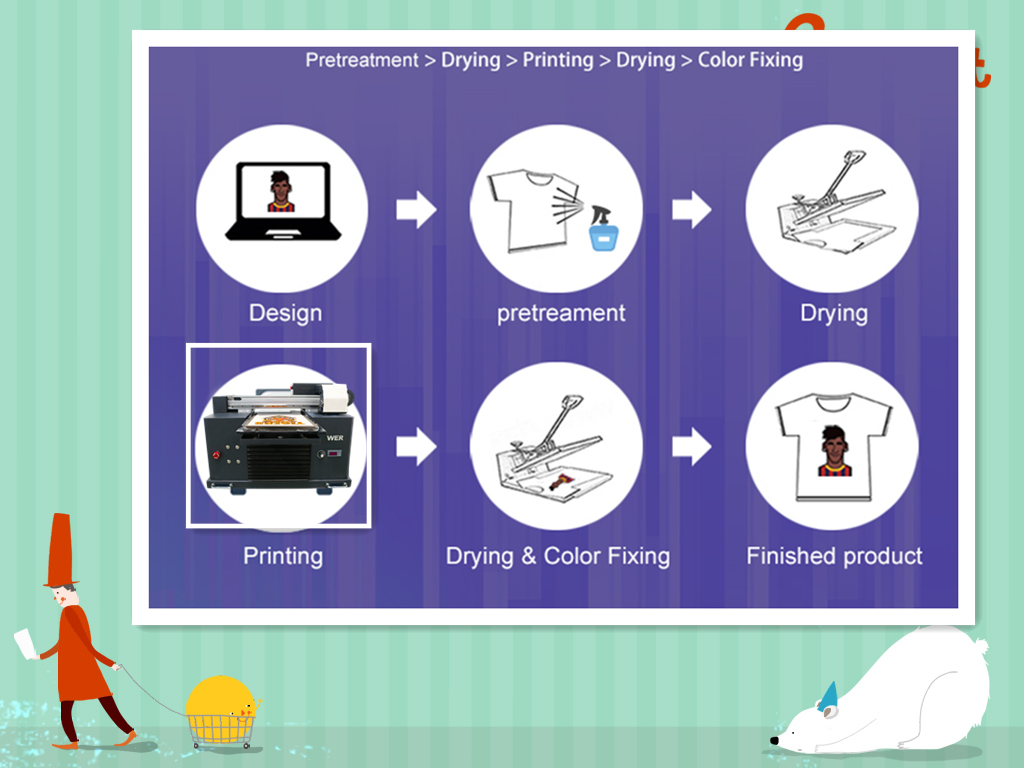

1. Direct to garment printing: it is also called DTG printing, a process of printing on textiles using specialized ink jet technology, it prints on fabric directly, easy operation. Unlike sublimation printing and screen printing, there is no long setup or clean-up process, and DTG has the ability to print just one single shirt for minimal cost. Besides t-shirt, DTG printer also has good print quality on trousers, bags, shoes, hats, pillows, etc.

- Sublimation printing: it prints on sublimation paper first, then heat transfer to the fabric.

- Screen printing: it is one of the early methods of printing. It involves the passing of ink or any other printing medium through a mesh or ‘screen’ that has been stretched on a frame, and to which a stencil has been applied. The stencil openings determine the image that will thus be imprinted.Secondly, we introduce the difference between DTG printing and sublimation printing:

1. The difference in use

DTG printing: input color picture into computer, adjust the size, position the printer, output printing, and press the heat press machine for about 15 seconds after printing. A piece of clothing is printed. Simple, low cost, easy to operate.

Sublimation printing: ordinary printers use special heat transfer paper, transfer ink, print on the transfer paper, and transfer the pattern on the transfer paper to the clothes through the high temperature of the transfer machine. The cost is about US$0.3 for a transfer paper. Meanwhile, it requires high temperature for the heat press machine. Uneven temperature may result in incomplete transfer and scrap.

2. In printing effect

DTG printing: The printed white t-shirt has no hand feeling and it has very good breath-ability. The black t-shirt has a slight touch feeling and the breath-ability is still good.

Sublimation printing: The printed white t-shirt has a thick feeling and a gel texture. Black t-shirts are overweight, so sublimation printing are not used to print black t-shirts normally.

3.In fastness

DTG printing: Washing fastness of 4 grades on white t-shirts, 3.5 grades on black t-shirts, no fading or falling off.

Sublimation printing: Several times of water washing will cause it to fall off.

4.Cost

DTG printing: A4 size print on a white t-shirt, the cost is about 0.08 US dollars. The black T-shirt is about $0.24.

Sublimation printing: The transfer paper is about US$0.3, and the ink is not included.

Then, why is Screen Printing Different than Direct to Garment Printing?

Direct to Garment Printing does not use screens and can be done with a more traditional printer. This does cut down on costs, due to not having to set up or use screens, as well as cutting down on mess and clean up since there is no rolling inks through screens. Additionally, digital direct to garment printing is a newer technology, it can print on white and dark t-shirt directly, convenient. Screen printing can also be done on a variety of substrates whereas direct to garment can only be done on cotton and cotton blend materials.

Screen printing yields only 72 DPI at its highest, while Direct to Garment printing has a resolution of 1440 x 1440 DPI, the print effect is much more clear, allowing for near-photographic clarity, with no halftone dots. So depending on the size of your run, the type of garment you need printed, or the art required, direct to garment printing may be a perfect fit. For instance, since using a digital direct to garment printer is faster and less expensive than screen printing, there are often no minimums allowing for greater personalization of the garment at lower costs. Maybe you need just one customized t-shirt as a gift for a friend.

So in summary, DTG printing machine is the most suitable choice for t-shirt printing at present.

With the improvement of apparel-specific inks, the color fastness problems that previously plagued T-shirt apparel printers have been completely solved. The industrial application of T-shirt printers has been realized, and the traditional screen printing technology has been completely replaced in the process. The printing effect is better than the traditional printing effect! Here I will talk about how to choose a good T-shirt printer, which T-shirt printer is good? How to choose a good T-shirt printer? T-shirt clothing printer Which one is better?

Selection of print head

Here is a comparison of the several commonly used nozzles: Epson, Ricoh, Seiko.

These three nozzles are from three different groups in the Japanese country, each with its own advantages:

1.Epson print head mainly prints water-based ink, its ink droplet is only 3.5pl, the printing precision is the highest, the color is bright, suitable for the printing of products with high precision requirements!

2.The disadvantage of the Ricoh nozzle is its high cost and high cost. Gen5 variable ink dot 7-35PL, but it is an industrial nozzle, printing speed is fast, service life is longer. But the fineness is not good enough!

3.The shortcomings of the Seiko nozzle, because it is an industrial nozzle, to ensure that the head is not blocked, the inkjet point is relatively thick, 35pl. The precision printing is not high, so the particles of the printed product are relatively large. Generally suitable for large-format printing advertisements, printing small-format materials is not accurate enough. Nozzle life is generally used for 3 years

So in summary, the general T-shirt printing format is not very large, and the T-shirt pattern requires high precision, so the T-shirt printer of Epson print head is the best choice!

Selection of machine model

Generally, manufacturers have A3, A2, A1 and other T-shirt printers of various formats. According to one’s daily output and demand to purchase the suitable machine!

Selection of machine manufacturer

Here we have to talk about the difference between modified machines and other brands of machines. Because the market space for flatbed printers is very large, many new companies have been established, but a machine needs about 3 to 5 years from R&D, testing to the final market. For a company that has only been established for a few years, how can such a technology precipitate, the only way for them to enter the market is to fight the price war, the cost of the modified machine is already low, if you buy it, then congratulations, you have become the machine tester of other companies. Therefore, the company must choose the company for more than 5 years. They have done so long, they must have their own core technology precipitation, and have their own research and development strength, so the machine is more stable! The printing effect is better!

Shanghai WER-China Industry Co., Ltd, www.wer-china.com, is a company specialized in digital printing machines since the year of 2009, products are exported to more than 50 countries all over the world. If you have a requirement or any question about the printing machine, welcome to contact us freely.

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | |||||

| 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 17 | 18 | 19 | 20 | 21 | 22 | 23 |

| 24 | 25 | 26 | 27 | 28 | 29 | 30 |

| 31 | ||||||

Recent Posts

- Ultimate Guide to UV Printing: Insider Tips and Tricks

- Before You Invest: Choosing a Large Format Flatbed Printer

- Maximizing Brilliance: Mastering UV Printer Settings for Optimal Media Reflectivity

- The advantages of using a WER UV printer for large format printing (2)

- Achieve Stunning Results in Home Décor and Architectural Design with UV Printer

Archives

- January 2025

- November 2024

- September 2024

- March 2024

- December 2023

- November 2023

- October 2023

- May 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

- December 2017

- July 2016

- June 2016

Recent Posts

- Ultimate Guide to UV Printing: Insider Tips and Tricks

- Before You Invest: Choosing a Large Format Flatbed Printer

- Maximizing Brilliance: Mastering UV Printer Settings for Optimal Media Reflectivity

- The advantages of using a WER UV printer for large format printing (2)

- Achieve Stunning Results in Home Décor and Architectural Design with UV Printer

Recent Comments