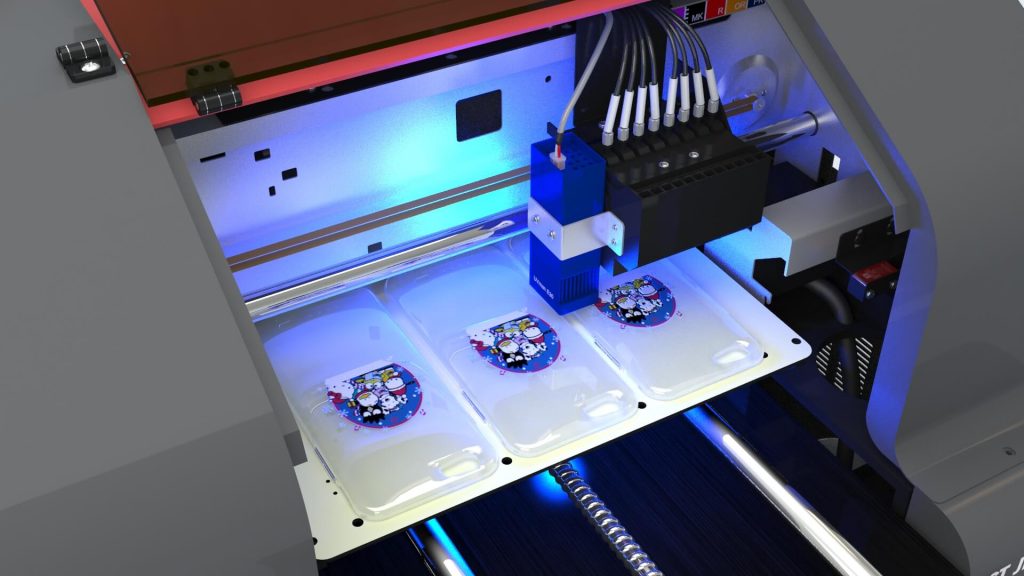

UV printing is considered to be versatile, because it can print directly on substrates of various materials. But do you know that when printing on metals, tiles, plastics, glass, and other media with smooth surfaces, you need to do pretreatment process?

What is the function of pretreatment? How to do pretreatment on medias?

What is the function of pretreatment? How to do pretreatment on medias?

These are difficult for beginners, if they don’t understand in advance, it will easily cause a lot of troubles in operating the machine. In some special cases, they may buy a printer that is not suitable for their applications, which is a waste of money.

Benefits of the pretreatment process:

If the substrate is metal, glass, acrylic, the surface needs to be pre-treated before printing. Make the ink firmly adhere to the smooth surface, enhance color performance and fastness.

Better print quality

If you print directly on some smooth non-absorbent substrates, the final print quality will be poor, but it will be perfect after the coating process. No matter the printed piece is bent, folded or placed for a long time, there will be no cracks on the surface.

Instant drying speed

The coating liquid is made of special chemical component, it can be dried within 3 minutes after spraying, especially on smooth materials, such as glass, ceramic tiles and metal.

Wear-resistant and waterproof

The coating liquid has adhesive ingredients. After sprayed, the contact effect of the ink on the material is very good, and the final printed matter has higher wear resistance and water resistance than non-pretreated print.

How to preprocess media?

Use a coating liquid brush or electric spray gun to spray the coating liquid on the surface of the media.

Common– used coating liquid

The coating liquid is different. Not all materials require a pretreatment process. Not all materials require the same coating fluid.

For more details, welcome to contact us freely.

Better print quality

If directly print on some smooth-faced, non-absorbent substrates, the finished print has bad quality, while perfect after the coating process. No matter the print is bent or folded or placed for a long time, the surface will not appear cracking, fault…

Instant drying speed

The pretreatment liquid is made of special chemical materials, which will be dried within 3 min after spraying, especially on the smooth materials such as glass, ceramic tiles, and metal.

Wear resistant and waterproof

The pretreatment liquid has adhesive ingredients. After pretreatment, the ink is superiorly touched on materials, the finished print is far more wear-resistant and waterproof than non-pretreatment print.

How to Pretreat Media?

Use a pretreatment liquid brush or electric spray gun to spray pretreat liquid on media surface.

Common-used Pretreatment Liquid

The pretreatment liquid are different. Not all materials need pretreatment process. Not all materials need the same pretreatment liquid.

Recent Comments