The application scenarios of dark surfaces

Dark surfaces offer unique application scenarios for UV printer. Here are some common examples:

1. Customized Apparel: Dark-colored clothing, such as black t-shirts or hoodies, provide a great canvas for UV printing. You can print vibrant and detailed designs, logos, or artworks directly onto the fabric, creating personalized and eye-catching garments.

2. Promotional Items: Dark surfaces, like metal or plastic pens, keychains, or phone cases, can be printed with UV technology to add branding elements, company logos, or personalized messages. This allows for customization and enhances the visual appeal of promotional products.

3. Signage and Displays: Dark-colored signboards, acrylic panels, or banners can be printed with UV ink to create visually striking advertising materials. The UV ink stands out vividly against the dark background and ensures excellent color saturation and durability.

4. Home Decor: Dark surfaces in home decor, such as wooden or glass frames, ceramic tiles, or decorative items, provide opportunities for UV printing. You can add intricate patterns, images, or personalized designs to enhance the aesthetics and uniqueness of these objects.

5. Automotive Accessories: Dark surfaces in automotive accessories, like car dashboards, interior panels, or motorcycle helmets, can be customized with UV printing. This allows for branding, adding logos, or creating detailed designs that complement the overall style of the vehicle.

These are just a few examples, and the possibilities are endless. UV printing on dark surfaces enables creativity and the ability to add personalization or branding to a wide range of products and materials.

How to print on dark surfaces with a WER UV printer

Printing on dark surfaces with a WER UV printer requires a slightly different approach compared to printing on light surfaces. Here’s a step-by-step guide to help you achieve excellent results:

1. Prepare the artwork: Make sure your design includes a white layer beneath the colors or images you want to print. This white layer acts as a base to enhance the visibility and vibrancy of the colors on dark surfaces.

2. Set up the printer: Adjust the printer settings to accommodate the dark surface. Increase the white ink opacity to ensure proper coverage and use the appropriate curing settings for optimal adhesion.

3. Test and calibrate: Before printing on the actual dark surface, conduct test prints on a similar material to fine-tune the color settings, ink density, and curing time. This will help you achieve the desired outcome and avoid any potential issues.

4. Print with precision: Load the dark surface onto the printer’s flatbed or roll-to-roll mechanism, ensuring it is securely positioned. Send the print job to the printer, making sure the white layer is printed first. Follow the printer’s instructions for proper printing and curing.

5. Post-process and inspect: Once the printing is complete, carefully remove the printed dark surface from the printer and allow it to cure fully. Inspect the print for any imperfections or areas that may require touch-ups.

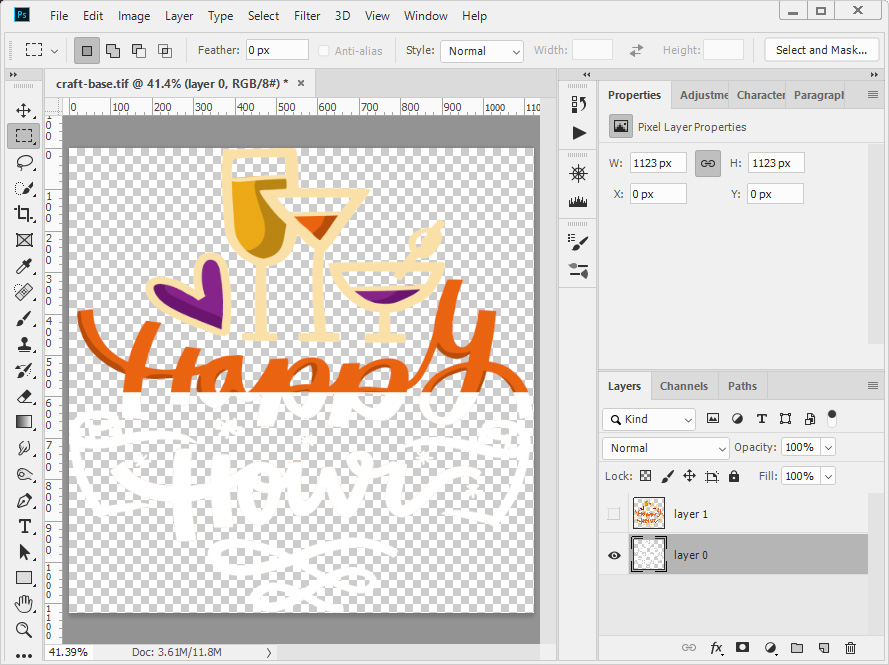

Below is a video of the WER A3 E3055UV printer printing patterns on a dark wooden Craft Base:

Remember, it’s crucial to follow the manufacturer’s instructions and guidelines specific to your WER UV printer model for the best results. With practice and experimentation, you’ll master printing on dark surfaces and unleash your creativity.

Tags :

Knowledge & Stories| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| 21 | 22 | 23 | 24 | 25 | 26 | 27 |

| 28 | 29 | 30 | ||||

Recent Posts

- Ultimate Guide to UV Printing: Insider Tips and Tricks

- Before You Invest: Choosing a Large Format Flatbed Printer

- Maximizing Brilliance: Mastering UV Printer Settings for Optimal Media Reflectivity

- The advantages of using a WER UV printer for large format printing (2)

- Achieve Stunning Results in Home Décor and Architectural Design with UV Printer

Archives

- January 2025

- November 2024

- September 2024

- March 2024

- December 2023

- November 2023

- October 2023

- May 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

- December 2017

- July 2016

- June 2016

Recent Posts

- Ultimate Guide to UV Printing: Insider Tips and Tricks

- Before You Invest: Choosing a Large Format Flatbed Printer

- Maximizing Brilliance: Mastering UV Printer Settings for Optimal Media Reflectivity

- The advantages of using a WER UV printer for large format printing (2)

- Achieve Stunning Results in Home Décor and Architectural Design with UV Printer

Recent Comments