Do you have an ink estimating program for inkjet printers in your workshop?

It may be bundled with your digital press, or you may have proactively purchased a solution designed to help you estimate the amount of ink needed to produce your job. It may be a stand-alone procedure, or it may be part of a data sharing agreement to update your purchasing, inventory, and quotation/valuation systems.

It may be complex, or it may be a spreadsheet that requires human interaction. They come in various shapes, sizes, and accuracy, so understanding what you have and how it works can help you avoid pricing errors and manage inventory expectations. In other words, if you don’t know how estimation happens, how can you apply this information to your business?

The place to start is the ink estimator you are using. Earlier this year, a survey was published for owners of production inkjet machines, asking them about their use of ink estimation tools. Although not all respondents use ink estimators, two-thirds of the respondents use ink estimators provided by hardware vendors for free. Some people develop it themselves, while others buy a solution. The survey tells us that 79% of respondents believe that ink estimation is very important or very important to their estimation process. It also tells us that 81% of respondents found that ink estimation gives them a competitive advantage in certain types of jobs.

This is good news for those who provide ink estimators. The implication is that if you have the opportunity to use the ink estimation program, you should use it to gain an advantage, but this brings us back to understanding the meaning of ink estimation and how to use it. For any ink estimator, no matter how complex or integrated, you should still compare what the estimator tells you in advance with the actual ink usage, so you can evaluate its accuracy and adjust your assumptions if needed .

First ask the provider of your ink estimator, how their ink estimator is designed, and then follow up on these questions so that you understand what the ink estimator wants to tell you.

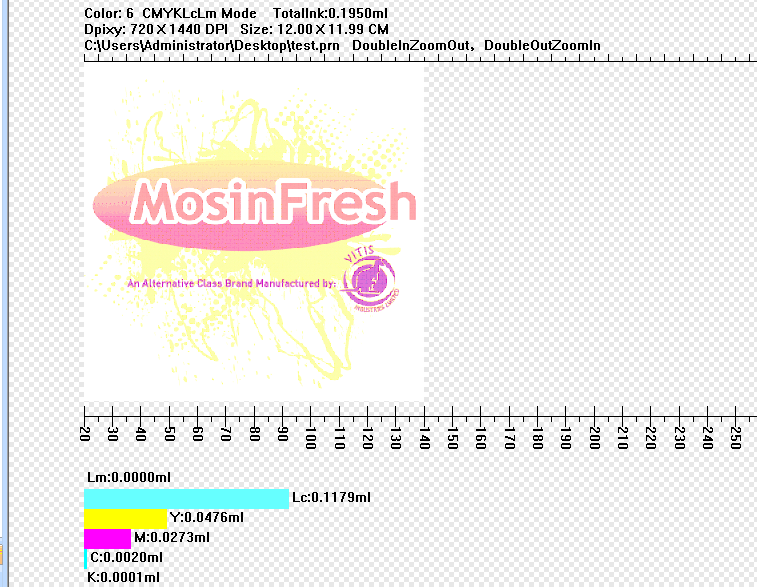

1.Does the ink estimator use the same RIP as DFE to estimate the number of ink drops of each color in the target job?

Not all ink estimators are built the same way. Some use the same RIP. Some use emulators. Some use a separate program to estimate the amount of ink based on the size of the ink droplets (some use multiple droplets in the same job) and information about the print head technology. Some use various techniques to aggregate estimates. Each type of estimator has value, but knowing the technology can help you set expectations for the accuracy of your estimates. For commercial purposes, an estimate with an accuracy of 95% is very different from an estimate with an accuracy of 85%. No matter what the supplier tells you, run some tasks to test your actual ink usage against the estimator’s prediction.

2.Does the ink estimator understand the medium that will be used for the target job?

Some papers are more absorbent and require more ink to achieve the desired print quality. Your ink estimation program may have an option to provide media specifications. If so, please use it. The more details it accepts and uses, the more accurate your estimates will be.

3.Does the ink estimator use a color profile that you can control?

Some ink estimators make assumptions about the ICC profile, while others allow you to attach a target profile to the ink estimator at runtime. The information carried by the configuration file can make the estimation more accurate, so if you can attach it, don’t bypass this step!

The revelation is that no matter what type of printed matter in your catalog, the ink estimator can bring more accuracy to your quotations and estimates, but be careful! The ink estimator program provides information that you can use, but It would be an error to use them without testing. Believe, but verify. You should periodically compare estimated values with actual values. You may need to adjust how you estimate the system that uses this data.

Therefore, it is generally difficult to accurately estimate the actual amount of ink used. It can only be calculated by traditional methods and checking the amount of ink used. Different environments will lead to different ink consumption. If you want to know more about how to calculate ink consumption, you can contact our company’s professional and technical personnel, we will give you a satisfactory explanation and answer.