Ordinary ink-jet printers are mainly printing on roll materials like ink-jet cloth, flex banner, canvas, tarpaulins, single-hole mesh, etc. UV ink-jet printer can print on acrylic, glass, wood, metal, and other flatbed materials.

Ordinary ink-jet printers are also called traditional eco solvent printers. Most of them use commercial-grade Epson print heads, which can print pictures with high resolution, but they cannot be produced in large quantities for a long time, and they use different inks. UV ink-jet printers use UV ink, while ordinary ink-jet printers use eco solvent ink and solvent ink.

The principle is different:

- the UV ink-jet printers follow the principle of UV-LED curing.

- UV-curable ink is a newer product than eco solvent type.

- It is cured by cross-linking the ink components through ultraviolet light.

- It is basically free of VOC (Volatile Organic Compound), and it is suitable for a variety of substrates, and has a larger development space.

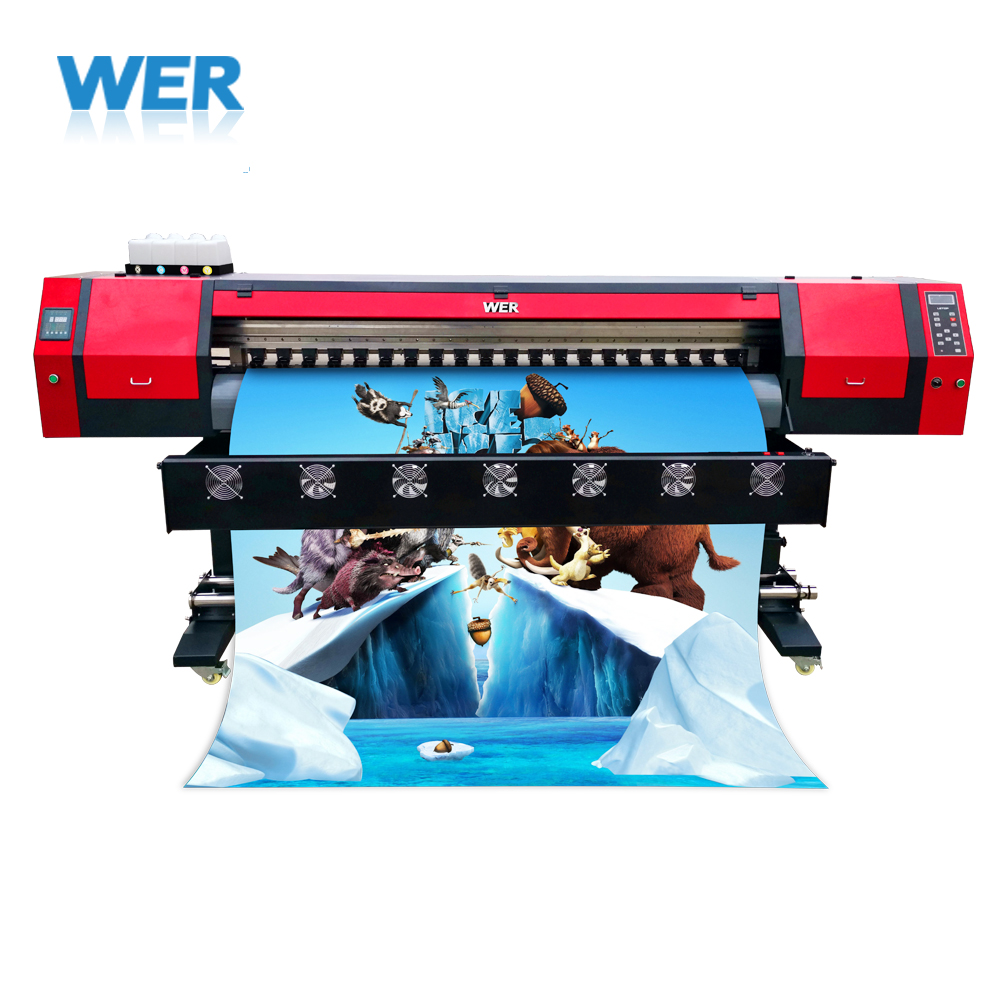

Nowadays, the ink-jet printers used in the market are generally 3.2 meters or 5 meters, and they are mainly used in the advertising industry for large outdoor advertising. Initially, the ink-jet printers used in China were imported, with high precision and high prices. With the development of the domestic ink-jet industry, nowadays, except for the main core components which are imported (such as print heads), the rest of the components have basically been localized.

UV flatbed ink-jet printer is the perfect combination of UV curing ink and digital ink-jet printing technology, and its appearance has been widely recognized by customers. UV flatbed ink-jet printers can perform color ink-jet on the surface of a variety of materials, which is the development trend of digital ink-jet printing technology. Using this technology, you can spray whatever you want, with fast speed and high accuracy; it not only has common advantages, but also realizes a multi-purpose machine. In contrast between the two, the latter is better than the former in the printing range and printing effect.